Automated Warehouse Systems: ASRS Raking System In Bangladesh

Ornate Technology Bangladesh is a pioneer and premier supplier of cranes lifting services within Bangladesh established. Ornate Technology Bangladesh provide expert advice in lifting services in the construction, industrial, power plant and oil & gas sector in Bangladesh. We operate a fleet of well maintained and up to date cranes ranging from capacity 1 tons to 45 tons. We are specializes in providing tailor-made AS/RS Raking solution for a diverse range of clients and industries. Whether you’re looking for new cranes supply or installation or a reliable Automated Warehouse Systems ASRS Raking System In Bangladesh maintenance service make us your best choice for quality, consistency and cost effective.

What is ASRS?

The Automated Storage Retrieval System’s history dates back to the early 1960s. Automated systems are generally used for providing extremely high-density storage in warehouses. ASRS systems are typically very tall, with some approaching 100ft tall. By using the height of your warehouse, ASRS mechanisms significantly reduce aisle space and achieve maximum density. This storage solution is much more compact than standard pallet rack systems. To buy an ASRS system for your warehouse, call +88 019 22775577 or click the contact button.

Specifications of ASRS Raking System: Automated Warehouse Systems

Ornate Technology Bangladesh is committed to providing Automated Warehouse Systems: ASRS Raking System In Bangladesh with superior services. Our maintenance services are available to our customers located all over Bangladesh. We offer breakdown service, operator training, emergency service, preventative maintenance, and upgrade services.

ASRS can be tailored specifically to fit the needs of your storage operation. Whether you need to move whole pallets or high-velocity case and piece storage and retrieval, an ASRS might be a great option for improving your material handling operation. These systems are highly integrative with forklifts already in use. Automated storage and retrieval systems monitor and manage your inventory with RFID and computer-controlled systems. With real-time data integration, product movements are recorded automatically, and storage audits and cycle counts can be reduced.

Advantages of Automated Storage and Retrieval System

Some advantages of an Automated Storage Retrieval System include reduced manpower needs and potentially reduced power in temperature-controlled areas like cold storage warehouses. Since the storage is so much denser, the power requirements can be less. The system can run 24 hours a day with no downtime. There are reduced errors in order picking and inventory with minimal downtime. They also have a higher throughput. In the long run, a system like this saves time and money.

Moving pallets and packages around your warehouse is not always easy. We know that managing a warehouse has many challenges for distribution center managers like you. Some of these challenges include high labor costs, low productivity and efficiency, and high safety risks for employees.

To overcome these challenges, our clients have success with automated storage and retrieval systems or ASRS. Currently, more than 10% of warehouses in the US use automated warehousing equipment. What about yours? But does your warehouse really need an automated warehouse system? How can they help your warehouse optimization efforts? Well, let’s learn what ASRS is, its use cases, its benefits, and more.

Defining Automated Storage & Retrieval Systems

Automated storage and retrieval systems are often referred to as AS/RS or ASRS systems. These systems leverage software, computers, and robotics to streamline handling, storing, and retrieving items in a warehouse. They can be small but can also scale into a comprehensive automation network controllable via an appropriate software solution.

ASRS leverages the synergy of many different technologies and vehicles to automate the retrieval and deposition of high-volume loads. Moreover, they do it accurately whether the load needs to be loaded in a storage unit or taken out from it and transported elsewhere.

The ASRS system’s technologies range from unit-load and mini-load AS/RS to horizontal and vertical carousels. The technologies used in an ASRS system dictate its type, and there are several of them.

Schedule a FREE professional consultation with our Total Industries warehouse optimization experts to find out if an ASRS would fit your needs.

Different Types of ASRS

What are the types of ASRS? We’ve already stated that ASRS depends on the technology it uses to automate load transportation.

Here are the most often used types of these systems:

Unit-load ASRS : they are used for large loads such as cases of items or pallets. Unit-load AS/RS is used for loads often weighing several thousand pounds. It uses fixed-aisle and moveable-aisle cranes;

Mini-load ASRS: they are smaller than unit-load AS/RS solutions. They are used for handling lighter loads. Mini-load AS/RS use shuttles and cranes, which makes them suitable for warehouses with narrow aisles;

Horizontal carousels: they are used for sorting small pieces and parts. Horizontal carousels leverage bins and rotate them horizontally to deliver goods;

Vertical carousels: they are similar to horizontal carousels. They rotate vertically, which helps maximize the use of storage space;

Vertical lift modules: or VLMs, are automatic inserters or extractors placed in the center of a column of trays. They help retrieve and store items in the trays.

Cube-based storage: this is a cutting-edge robotic picking system designed to operate in a cubical storage grid;

Shuttles: shuttles are often found in warehousing and manufacturing facilities that handle cartons, trays, and totes.

How to Know That You Need ASRS

First of all, you need to assess your warehouse operation to identify major pain points. Every warehouse is different, so you will discover various things that may or may not reflect the situation in other warehouses. Yet, there are specific challenges that only ASRS can help you overcome and future-proof your operation:

Generally speaking, every automated warehouse racking system consists of two major components:

Computer management system – it allows operators to schedule storage or retrieval processes and track inventory details (location, storage duration, items origin)

Storage and retrieval equipment – the hardware that does the job of loading and off-loading items

Modern ASRS can be installed very fast. They occupy a small footprint, thus allowing you to maximize the floor space in your warehouse. In addition, they are not too complicated to use, which minimizes the onboarding and training time.

How Much Does It Cost to Automate a Warehouse?

This is not an easy question to answer because the cost of ASRS varies depending on what you need. For instance, if you need only one standalone vertical carousel, automating your warehouse will cost below $100K. On the other hand, a fully integrated mini-load system that supports thousands of stock-keeping units might end up costing a couple of million US dollars.

Here are some of the factors that affect the final price:

• Size and weight of products

• Storage space

• Characteristics of the operating environment

• The cost of custom configurations to maximize the ASRS usability

• The cost of ASRS equipment, shipping, and installation

• Where to Find Professional Help for Your Warehouse Optimization

As you can see, whether or not to have an ASRS installed in your warehouse is not a straightforward decision. If you have limited experience with internal logistics automation, it can be hard to assess the needs of your warehousing operation.

There are a lot of factors in play. It would be best if you considered getting a professional consultation to make an informed decision.

Ornate Technology Bangladesh can help you discover if an ASRS would boost your warehouse efficiency. Request a professional FREE consultation or contact us online or by phone.

+88 01922775577

+88 01516726269

ornate.technology01@gmail.com

Schedule your meeting. Call us: +88 01922 775577 | +88 01516726269

Related Products:

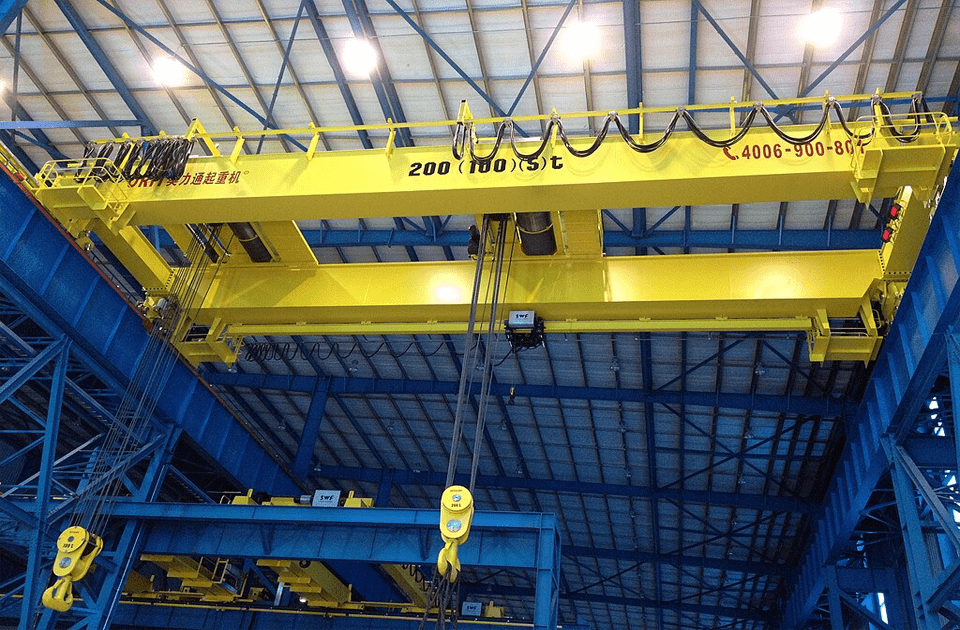

Overhead Crane Single Girder

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Jib Crane

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Overhead Crane Double Girder

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Tower Crane Top Kit

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Gantry Crane Single Girder

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Tower Crane Top Less

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

Gantry Crane Double Girder

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.

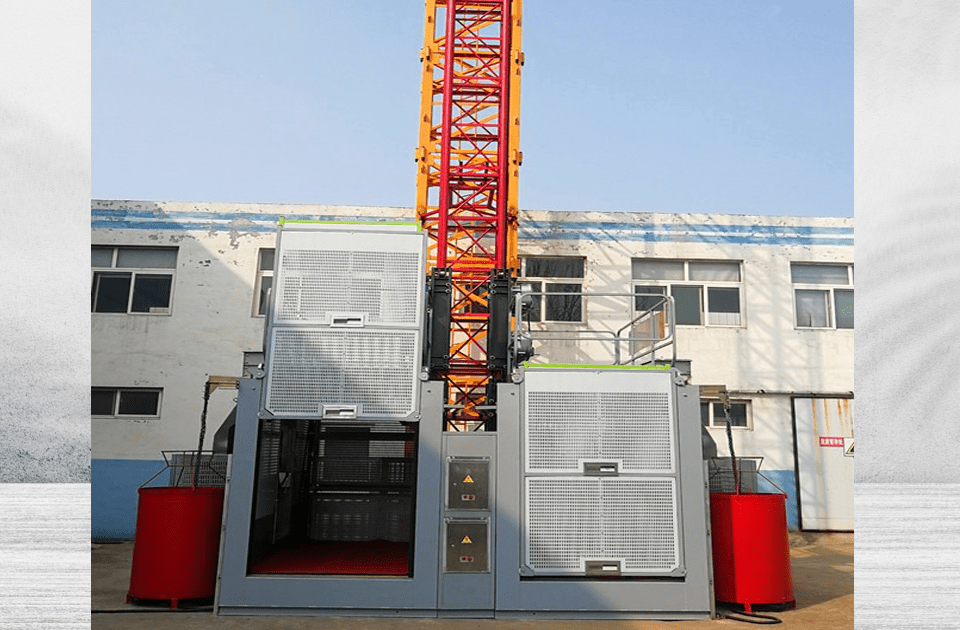

Construction Hoist

Ornate Technology Bangladesh is a master deport for all brands of Overhead crane, Tower crane , Ganty Crane , Jib Crane and Hoists.